The story behind

the

DMR Deathgrip

interview by Jamie Edwards / photos by Jamie Edwards & Jacob Gibbins

It won’t surprise you to know that some products in our industry aren’t original. They’re variations of a template, rebadged, retweaked, reworked. Legitimate and perfectly usable but nothing original.

Other products, the rare few, are original. They’re built from scratch, from the ground up, starting from a blank sheet and grown to a final, original product.

The DMR Death Grip is one of those – built by DMR’s Olly Wilkins from the raw talent and experience of Brendan Fairclough.

WO: Let’s start at the start. How did the Death Grip project come about?

Olly: We originally developed the DMR Vault pedal with Brendan’s help and ended up making a signature model. I guess another contact point was always going to be on the cards after the success we had with the Vault.

Contact points are an exciting thing to work on as they are the kind of thing that any rider will have interesting input on. To have Bren’s input is always well exciting – he rides like we all want to!

Why did you go with something totally new? Would it not have been easier to adapt an existing design like other brands do?

Yeah that would have been easier for sure! I don’t think that saving time and money is the primary concern in any brand that you would wanna buy into. DMR is a brand built around a passion for riding. You wouldn’t want to ride something which clearly isn’t considered. I wouldn’t anyway.

I guess its all about the story. Brendan has some insight, he’s got his PHD, Masters and doctorate in bikes. A guy like that can really articulate what needs to happen with a product and why. Not all riders can and not all brands have access to that.

And why Brendan? You obviously have a heap of riders on the books. Why go for him in particular?

I’ve kind of answered that above too. Obviously Bren happens to be one of my best friends. We’ve known each other since we were tiny little squids DREAMING about having signature products and riding all around the world. Those aims are still very much present! Beyond that and from a work perspective i’m a big fan too. Don’t tell him that though!

For me there are very few riders who can really encapsulate what it is about riding which is so fun. When you see Brendan ride it makes you want to. He’s the real deal. Simple as that.

You seem pretty excited about this one – maybe more so than any other DMR project I’ve seen you involved with. Why is this firing you up so much?

Its been a long time coming and a lot of work. It’s cool to see a project come to life after being involved every step of the way. Contact points are important components to get right and I feel like we’ve nailed it too. Obviously everyone has their own opinions. That said you gotta make something YOU are happy with or else you might as well buy something out of that Taiwanese catalogue you mentioned earlier

So how do you even start a project like the Death Grip?

We started by talking about it on a ride. Me and Bren agreed that we weren’t that hyped on existing grips and how it would be rad to make one of our own. I then approached my bosses about the project and they were instantly hyped to get on board. Its great working for a brand that are keen for these things as there is a huge amount of time and money involved in designing and making the simplest of products.

Can we talk about the overall design of the grip?

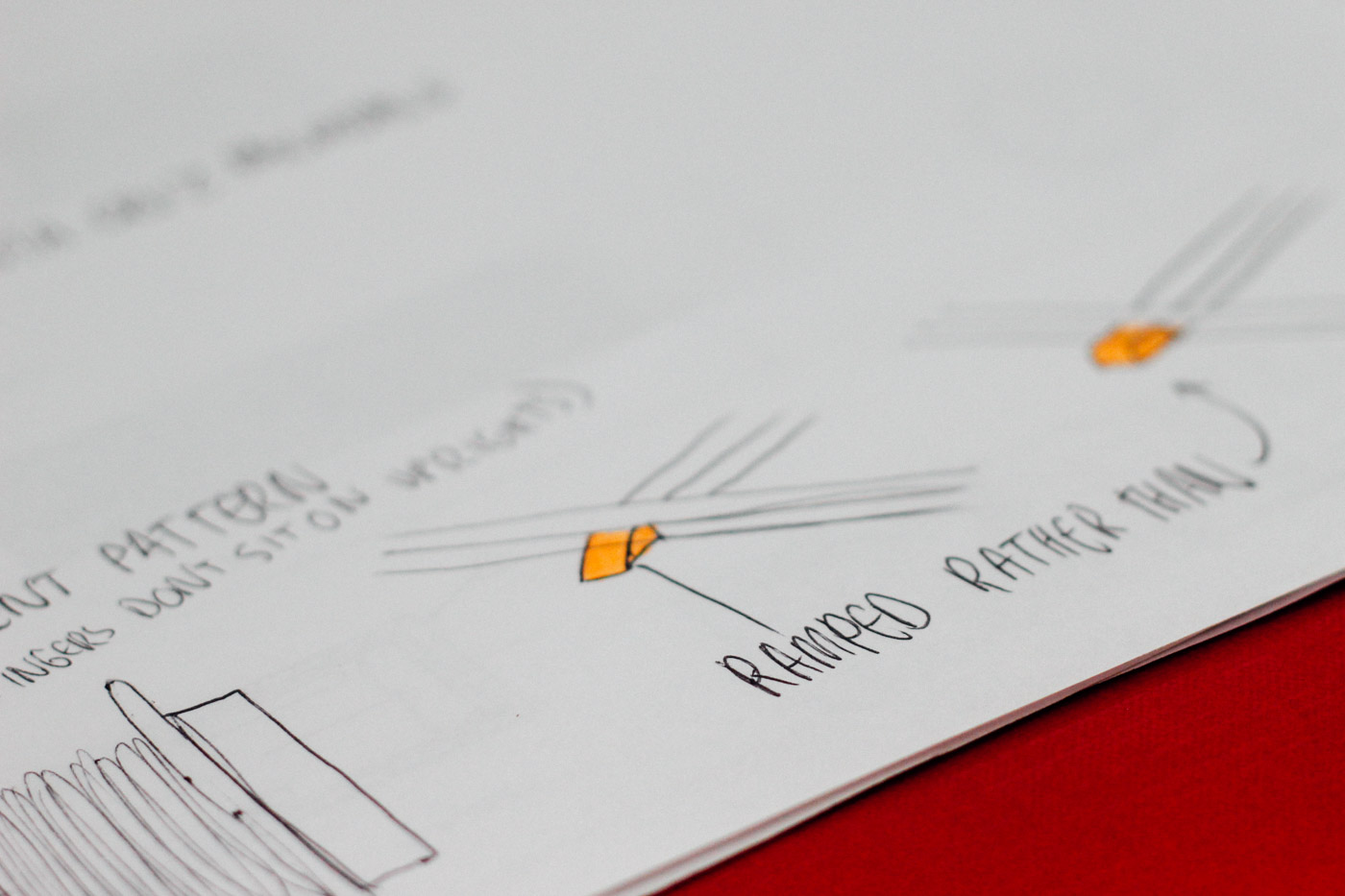

We actually started with a completely clean slate. We wanted to analyse every aspect, even down to the length. We made a list and worked from there on each point. You kind of go down the rabbit hole on a product like this. You’ll start something which you think will be easy and then three weeks later you are still looking at an individual knurl through a microscope and arguing over 0.05mm differences.

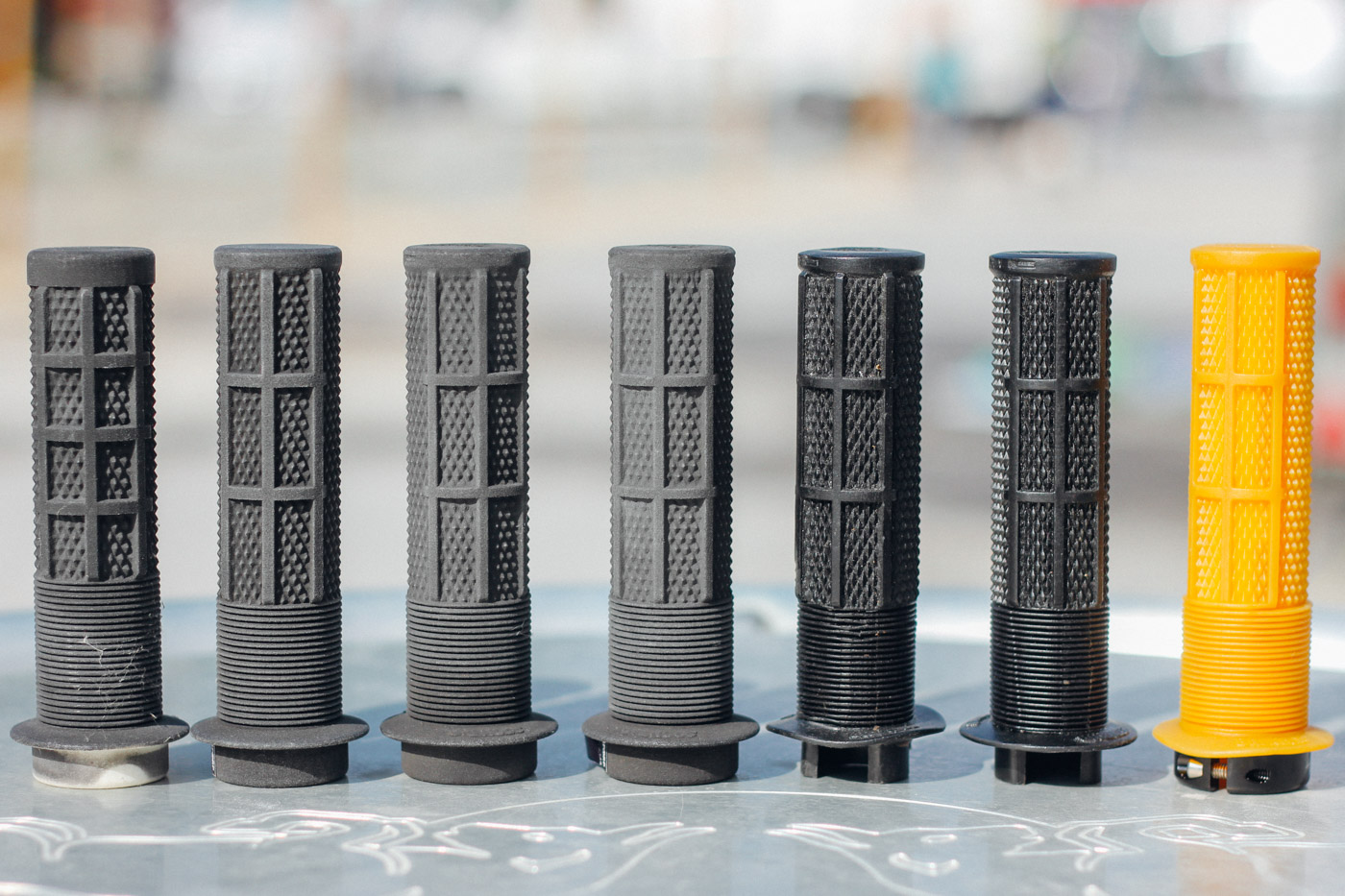

We started by shopping around for cores (the core is the inner most section of the grip – it’s a tube that the grippy rubber wraps around -Ed). We wanted the grip to be single lock but for there to be no movement on the outside of the bar. We found that a tapered core is the best solution to this problem and there’s something nice about how solid the grip feels when its on compared to another single lock grip. (The Deathgrip is narrower at the outside end than at the locking end – Ed).

Talk about me about the knurled section of the grip.

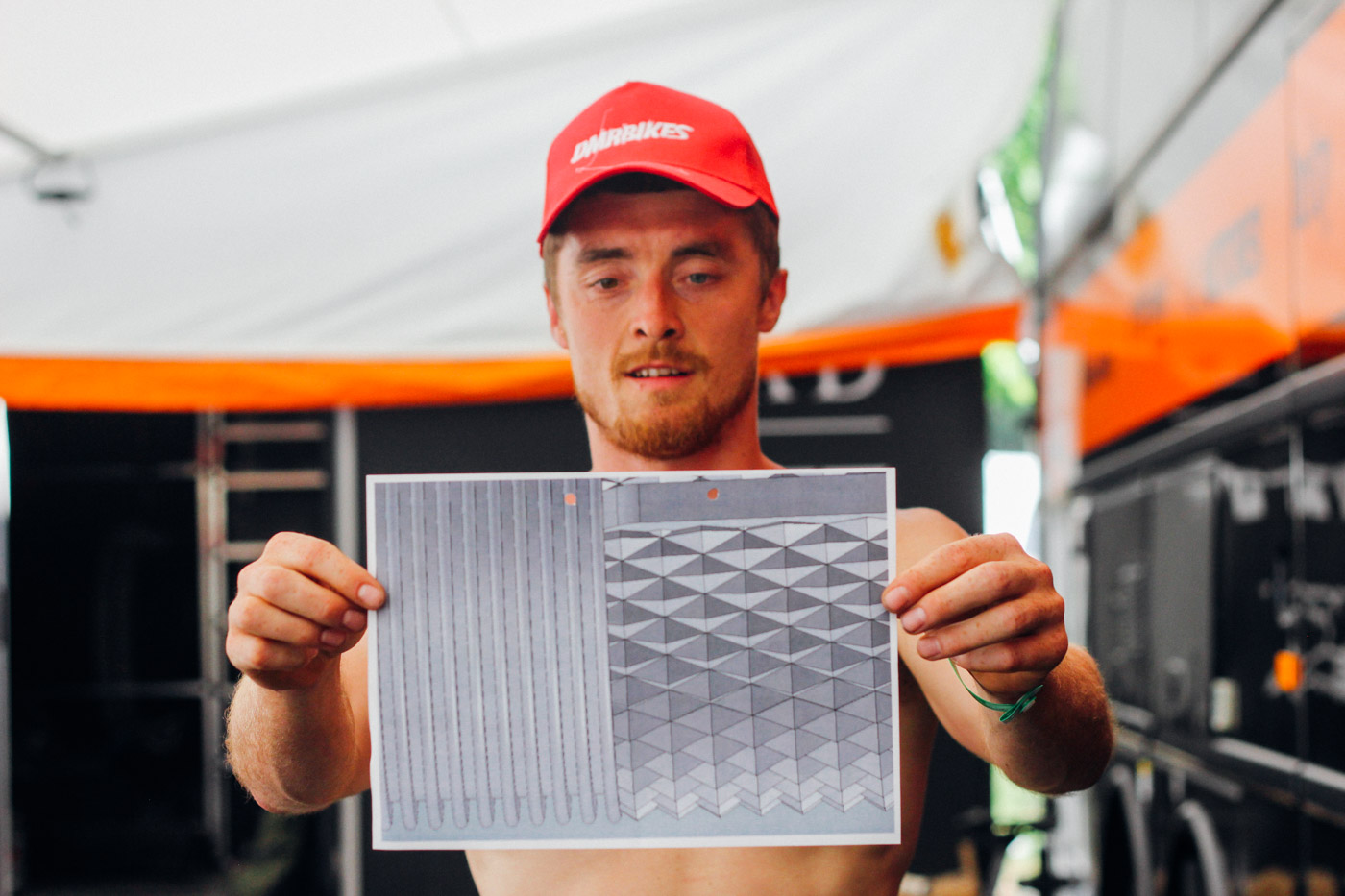

The knurled section of the grip is slightly more aggressive than a ‘standard’ knurl grip. When combined with a good compound its the best all weather option. Our knurl pattern deforms well when you hold on tight and it wears nicely to your hand.

Talk to me about the mushroom section.

The mushroom section is aimed at aiding with hand fatigue. Bren always felt that grips wore out there for a reason and that a malleable thumb pad would help when punching out laps. We obsessed over the heights on this part of the grip for a long time. We wanted it to deform to a similar height to which the knurl deforms to. This means it looks raised when your hand is not on the grip but when you hold on it’s exactly right.

… and about the flange

The flange is solely because it looks cool. We originally wanted to make some little neoprene grip donuts like you get on moto grips… they had even less function though!

… and about the grippy, moto section

That’s really useful in wet weather riding. Its also good to have an edge when you’re just holding on, particularly when your arms are burning and you’ve got a gap you need to clear.

You’ve included a few options for compound and size. How do you pin that down and say “yep, people will like this”?

I think that was largely about offering a range. It’s such a personal thing a grip. We didn’t want someone to like the shape and not the compound or vice versa. Interestingly Bren usually runs the thin version and switched to the thick for Fort William this year. He felt it was better for arm pump. It’s pretty cool to have those options.

So how does the process go once you’ve got a design nailed?

Yeah the design started pretty approximate at first. We cut up existing grips and got some rough numbers down on paper. For a contact point like this prototyping is mega important and we did a LOAD of different versions. The perfect grip on a computer screen might feel like you’re holding onto a potato in real life. Its pretty disappointing at times. You think you’re closer than you are.

“The perfect grip on a computer screen might feel like you’re holding onto a potato in real life.”

We tested the tapered core at first with a standard knurl pattern. In the meantime the first rapid prototype came back and highlighted lots of things we needed to improve on. At this stage the prototypes are made of hard material so you only get a rough idea to how it will feel. You’re really trying to nail dimensions. You’re looking at how long the mushroom section is, how it meets the knurl, how the end of the grip feels etc.

After numerous versions (both thick and thin) we got a rubber sample. This is actually just a rapid prototyped tool with rubber crudely poured into it. There are lots of imperfections which you have to look past. We could only then feel how the grip will actually deform when in use.

Once we were eventually happy with the shape we could finally ‘tool up’. This means that the final part of the development was the compound. We tried about 10 different options to work out the best combination of grip and durability. We ended up with a soft and a hard that we liked and spent as much time riding the samples as possible. The hiccups are kinda the most important things to learn from. I actually like hiccups as there is always a solution! Its the non-hiccups that involve a bit more thought.

How did you guys test out your design and your ideas?

It was so exciting when we got the first production grip onto a bike. We went out for a ride as soon as they arrived. That was a pretty cool feeling!

Brendan rode the Death Grip for almost an entire season before they were available for release. The time gaps between sampling and production are not always deliberate but we kind of feel that you can’t test something enough. We try to react quickly as a smaller component brand but at the same time its mega important that we don’t release anything sub-par or under-tested or under-considered.

At what point did you know it was ready to go and get into production? What happened at that point?

There are so many things to tick-off that there wasn’t really a ‘moment’. I guess actually giving the all clear on the order was a big point. By that point we had decided on colours, packaging, compounds, design. It was just a waiting game after that really. The grips are manufactured out in Taiwan so there’s lots of time involved.

The grip is priced at £16.99 in the UK – not the most expensive out there. What’s the story there?

Brendan, my bosses and myself all share the belief that its important to price products realistically.

If we don’t make pricing inclusive then its bad for all of us in the long run. I think we all remember being kids pretty vividly. The feeling of not being able to afford stuff was soul destroying at that age. ‘I want to be like Brendan but I can’t because his grips are aimed at 45 year old successful mens wallets’ Thats not what we wanted.

Bren set a price target at the very start of the project and we kept as close to it as possible. Its good to have that in sight from early on or else you set yourself up for disappointment!

“we all remember being kids pretty vividly. The feeling of not being able to afford stuff was soul destroying at that age.”

Was the Death Grip an easy process?

No I wouldn’t say it was easy. It was exciting all the way though. I guess you take on a bit of personal responsibility on a project like it. Bren took the lead on the grip and it was rad seeing him pumped on changes he wanted to make.

Timing is the only thing that ever pissed me off. When you’re excited about something the last thing you need is a 3 week long wait. Thankfully its a product that its hard to lose interest in. Your hands touch it every time you ride!

Obviously Bren has been out racing the grip … Did you nail it? Anything you’d like to have done?

I would say we are completely happy with it at this stage. After so long developing it we are keen to take a step back and listen to the feedback that riders give us. Right now we have not only Bren but half the World Cup DH pits on the Death Grip. If there are improvements to be made then we will get the feedback we need soon enough! It’s all good news so far.

And what’s next?

We currently have a tidy range of grips. The Death Grip caters for the AM/Enduro/DH/Lock-on market and the Sect (our full mushroom grip) caters for the Dirtjump, price point, non-lock grip customers. We want to add further colours and will be sampling any creepy new compounds that we can find in case there are improvements to be made. We might look into dual compounds. Who knows!

You can learn more about DMR bikes on their homepage

You can follow Olly Wilkins on Instagram

You can buy DMR Deathgrips here or look for your DMR local dealer here.