The Pipedream Full Moxie is the full suspension brother to their ever-popular Moxie hardtail and we’re finding out how it came together.

Pete caught up with Alan Finlay, the main man behind Pipedream and the recently-launched Pipedream Full Moxie, a steel, single pivot slayer.

Photos by Finlay Anderson.

What was the impetus for making a full suspension Moxie?

I don’t know how many times I’ve been asked, “when are you going to build a full suspension frame?” It had always been something I wanted to do, but I wasn’t going to build anything unless it ticked the boxes. The original Moxie was the ‘aha’ moment. I had some specific ideas about what I wanted the hardtail to be but the only way to build it was to get custom tubing made.

With the release of the Moxie, I realised that the steel full suspension I wanted, was possible.

Once you’d made that decision, what happened next?

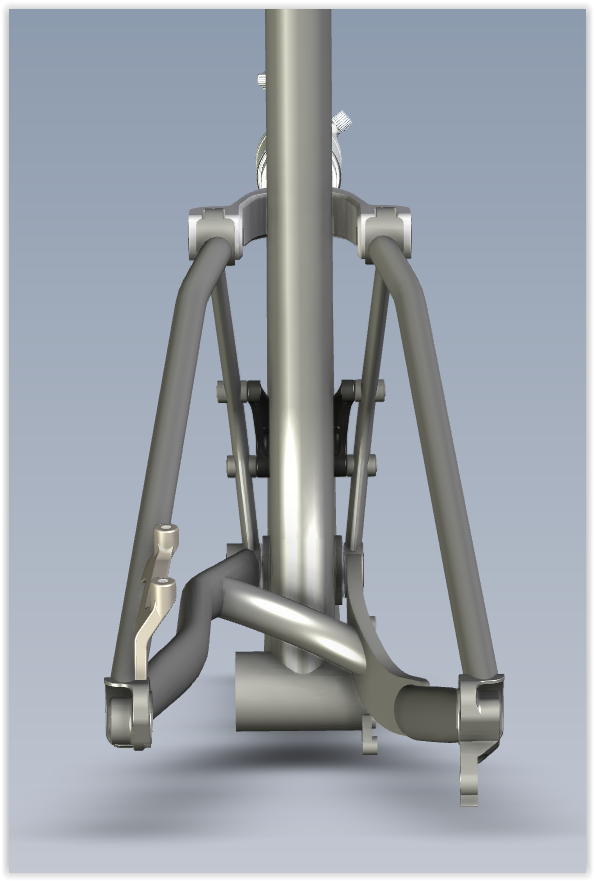

I’d always known what kind of frame it would be, a steel single pivot, but it had to have the same DNA as the Moxie hardtail with the same clean lines. Designing a full suspension frame is very different to designing a hardtail so if the Pipedream Full Moxie was to become a reality, I needed the expertise of the tubing and frame factory, and the assistance of friends in Taiwan who are designers, engineers and experts in their own right.

So, after bouncing some ideas and sketches back and forth for a few months, I headed out to Taiwan and we set to it. After a lot of talk, hard work, and a couple of informal meetings in a microbrewery, The Full Moxie was taking shape.

Who is involved in that process and what do they do?

I can‘t name names but the key people involved included a friend of a colleague of mine who’s a designer and an expert in CAD. He previously worked as a designer at one of the most reputable boutique frame factories in Taiwan; the other important contribution came from the tubing manufacturer and fabricators.

A bit of background.

The original Moxie hardtail was a concept bike, a Pipedream, it was a design that I didn’t think would be built. I sometimes call the Moxie the “improbable” bike as there wasn’t a downtube that was both long enough or suitable to actually build it. The longest commercially available butted down tube (I knew of) was 750mm long, but the down tube on the longer/510mm frame is 790mm.

Either the design had to be modified or we needed to come up with a solution. Short story, the tubes were drawn, we built the Moxie, painted it neon pink and took it to Eurobike, everything changed from that point onwards.

So, back to the Pipedream Full Moxie…

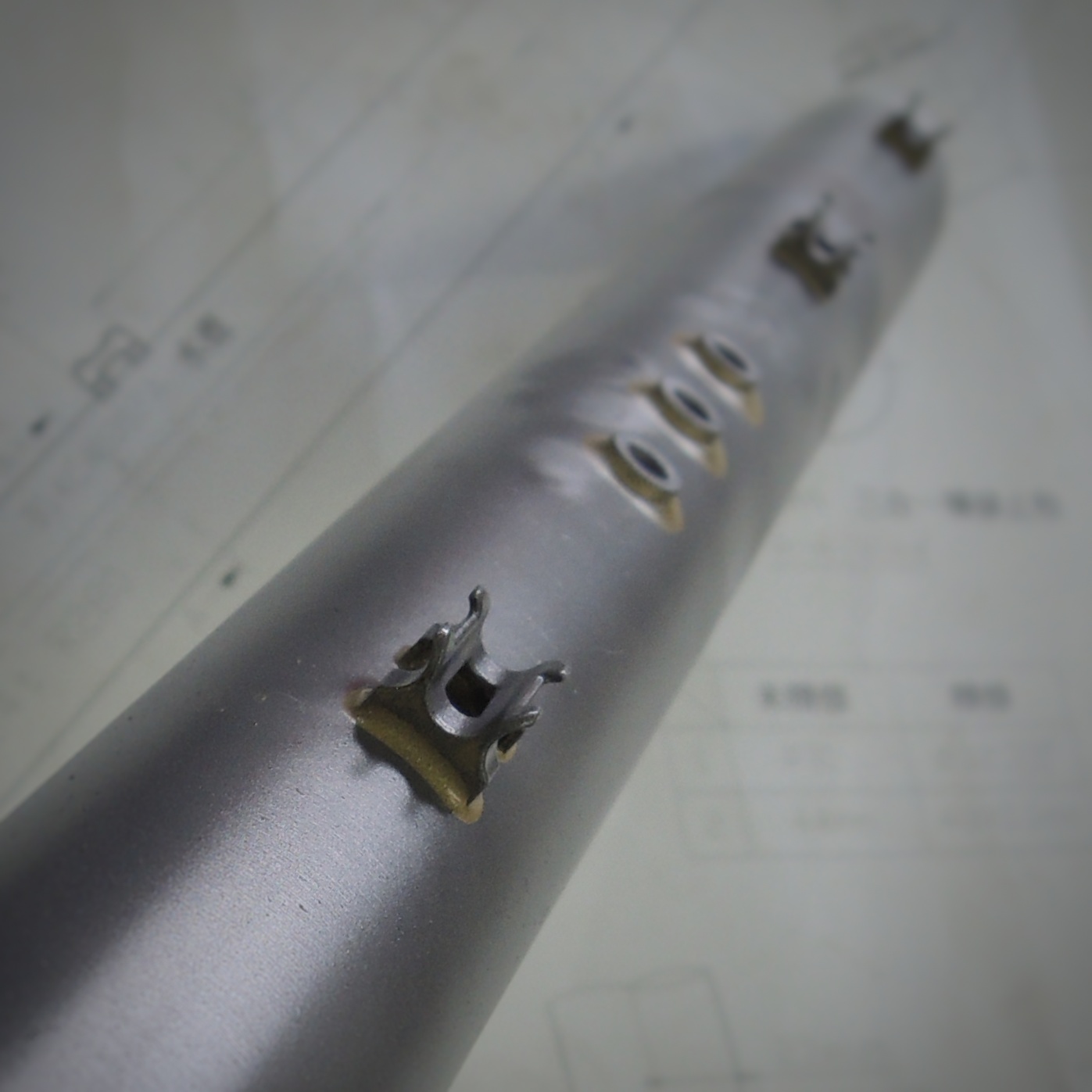

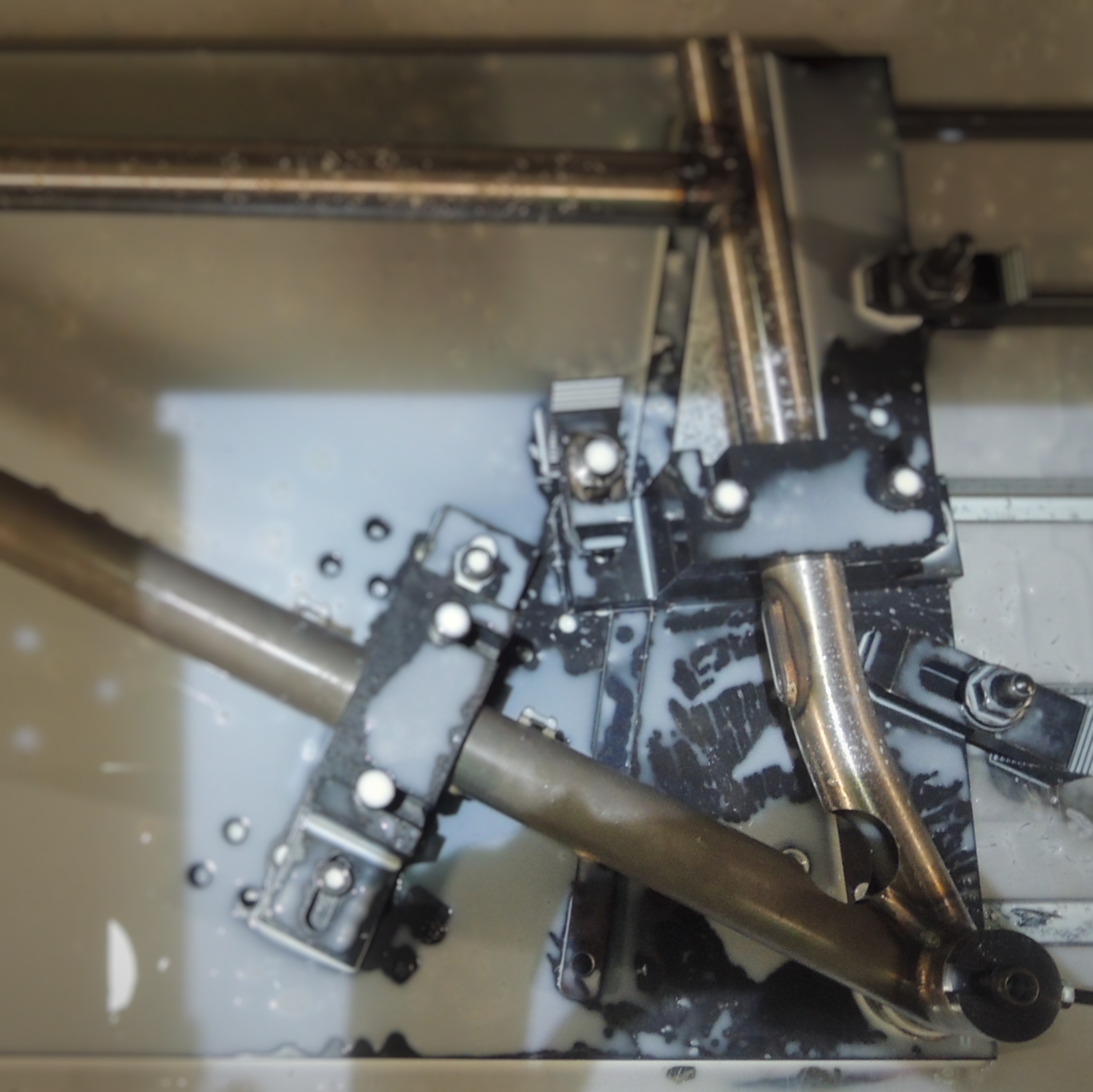

Once we had the 3D drawings, we could see what we needed to do to build it. Certain elements needed to be designed and fabricated from scratch, for example, the drive-side chainstay yoke, the bearing interfaces and the CNC machined frame hardware. The vertical curved tubes on the swingarm were specially made and required forms to be fabricated to bend and press them to shape.

Also, to have the same clean lines as the Moxie we needed a new down tube and top tube, that didn’t exist. Consequently, new tubes were designed to achieve the butting required for these special tubes. It wasn’t cheap but it meant I could build the bike the way I wanted.

What did you know you did and didn’t want to do with the Full Moxie?

I want a bike to boost the confidence of the rider and encourage them to push their limits, try something new, “ride their fears” and feel they’re in control.

The Pipedream Full Moxie also had to take the performance of the Moxie to another level, it had to put a smile on your face.

It had to look like a Moxie; it had to have the same clean lines and ‘organic’ flowing curves; it had to be beautifully simple and it had to be well-engineered.

And I didn’t want to make it over-complicated or do anything frivolous or unnecessary.

How did you narrow it down to a single pivot design?

I’ve ridden a lot of different full suspension bikes over the years, but I love the simplicity of a single pivot. I also wanted it to be completely made from steel so a single pivot is a sensible choice, in my opinion. As simple as the frame looks though, closer inspection reveals some important design features that really contribute to the overall performance of the bike.

Was it simply a case of adapting the existing Moxie geometry to the new bike?

I wouldn’t say simply but I wanted it to have the characteristics of the Moxie hardtail. The seat angle means that it’s got great climbing ability but also allows for a long reach as the effective top tube length isn’t uncomfortably stretched out. With long droppers, I can still have a short seat tube for a lot of stand-over.

A full suspension frame is different from a hardtail so as much as it looks similar and a few of the most-referenced numbers are the same, the dimensions of the frame and the geometry are different. That said, the feedback I’ve had from test riders is that it feels immediately familiar to them, especially if they’ve ridden the Moxie hardtail.

Again, it might look simple but making something that works well and is simple, is a pretty challenging task.

How did the tubeset change between the full and the ‘standard’ Moxie?

It’s all about the butting. Steel tubing has phenomenal strength and even the most ‘basic’ CrMo 4130 (or 25CrMo4 to use another designation) will typically be stronger than a 3Al/2.5 Titanium tube of the same diameter and thickness. When 4130 bicycle tubing is heat-treated, its strength can be increased by more than 60%, so it’s tensile strength becomes twice that of the aforementioned Ti.

Full suspension frames have different requirements to a hardtail. For starters, there’s a shock cradle in the middle of the down tube and on a hardtail, this is typically the thinnest section of the tube so the gauge and butt profiles of the down tube are different. The top tube also has different butt profiles to the hardtail and I’ve actually spec’d this tube on the updated 2020 Moxie hardtail.

The curved tubes between the main pivot and the yoke were custom formed to compliment the seat tube but the curves aren’t only for looks: they also create the space to fit the 3-dimentional CNC X-brace to resist torsion and the result is a more compact and stiffer swingarm than other layouts.

How did you fine tune what you wanted in terms of suspension performance?

It’s about balance or control. For example, it’s the difference between a pack of huskies working as a dog-sled team (in harmony) and several dogs on leashes pulling in opposite directions.

The suspension design, single-pivot, four-bar, VPP, etc., will determine many of the characteristics of the suspension performance. The things that can be tuned are leverage ratio, spring curve/rate, anti-squat etc. but it’s all about balance and delivering the optimal performance for the applications for which the bike was designed to excel in.

By using a relatively long stroke shock, the frame has a relatively low spring rate, making it well suited to modern high-volume air shocks. The yoke-activated shock also allows the kinematics to be tuned to create a slightly more progressive leverage rate too. It’ll also work happily with a coil.

I wanted The Full Moxie to offer the rider the ‘Goldilocks’ performance for the kind of riding that most people do most of the time. I wanted it to have small bump sensitivity, handle the big hits, have ground-hugging performance and deliver power to the ground efficiently. It needs to eliminate bob but not so much that the suspension isn’t doing what it’s designed to do. I feel that’s been achieved with The Full Moxie.

My goal is always to create a bike that responds both positively and predictably to the input it receives. I want the bike to boost the confidence of the rider and encourage them to push their limits, try something new, ride their fears while feeling they are in control.

The only variable I can’t tune is the rider which is why we need a bit of fairy dust.

How many prototypes did you have before you settled on the production chassis?

A small batch of prototypes was built and sent to several riders for trail-testing and their feedback. We also did ISO testing on the prototype just to make sure.

Between us we’ve been able to figure some things out and the result has been some tweaks to the design. With the updates made, the frames needed to be tested again so I suppose the production model is version 2.1.

All in all, it’s taken 18 months to take it from concept first draft to completion.

Beyond prototypes, what form did your testing take?

The bike was trail-tested in England, Scotland, New Zealand and Asia, in different conditions and on different kinds of trails.

It’s also been tested with different builds to get an indication of how this might affect performance. We’ve compared different fork lengths and offsets; air and coil shocks; shock stroke; rear wheel travel; wheel/tire sizes; bar/stem combos and even the effect of angle-sets on the geometry.

Did you have any outside help for testing?

Absolutely. I rode it myself but I’m not as good as I think I am, nor as fearless and reckless as I was 20 years ago so I always have as many people as possible ride and test a bike. It’s riders with the ability and skills to take it as close to the ‘red line’ as possible who give the most valuable feedback and this is a hugely important part of the development process.

Favourite moments?

The first time I saw the 3D render of the frame in CAD and got to ‘see’ the bike; when it passed ISO; hearing rider feedback and watching their videos; riding the final version of The Full Moxie for the first time

Any disasters?

No disasters. Besides, I’d not tell you if there were any anyway.

Anyone to thank?

Everybody who’s been a part of the development of the Pipedream Full Moxie: this is genuinely a team effort.

My wife. She’s supported me and encouraged me to keep taking risks; Mike, who works behind the scenes and is the (Welsh) power-house of Pipedream Cycles; Peter, who’s expertise and encouragement has been next-level; the team in Taiwan who were involved in the design and fabrication. Si, for his inexhaustible enthusiasm, his friendship and blunt honesty; and finally, Scottish Enterprise for their investment and vision for mountain biking in Scotland.